How Optimizing Inventory Leads to Increased Cash and EBITDA

In this volatile market, has the demand for specific products significantly increased or decreased, shifting your product mix? How are you managing excess inventory for some product categories and ensuring visibility and action on potential shortages in others? Balancing the amount of cash tied up in inventory and the service level to your customers can sometimes be challenging.

Why Inventory Management?

Inventory is one of the largest and time-locked expenditures in your business, so to protect cash and yield more profit you need effective inventory management and throughput optimization.

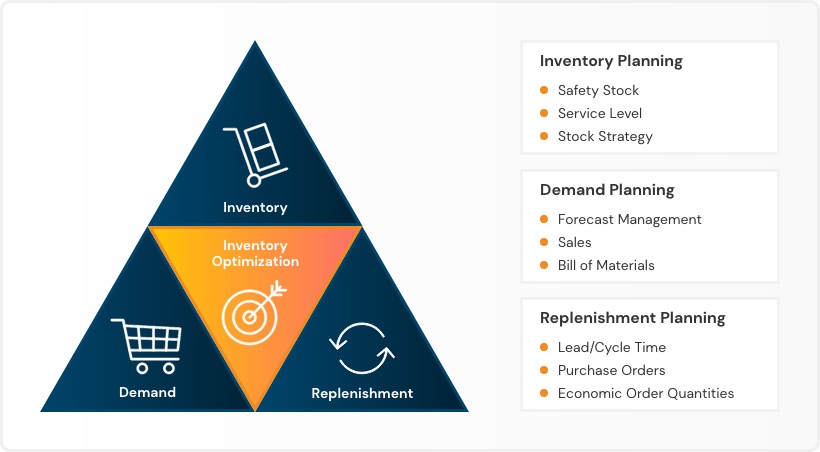

By “inventory management”, we mean the active supervision and control of non-capitalized assets (inventory) and stock items. Whether you are a manufacturer or a distributor, increasing the quality of your inventory through effective and efficient demand, inventory, and replenishment planning is key to keeping your costs down, and increasing throughput and profitability.

Ensuring you have more of the right products available in the right quantities in the right place and the right time yields:

- Increased return on assets

- Lower working capital (more cash on hand)

- Increased service level, on-time/in-full to customers

- Decreased planning and execution lead times

- Decreased freight and G&A expenses

- Reductions in non-value-added activity

As part of our engagements, we work with our clients on inventory management through a data-driven approach and sophisticated modeling to develop inventory management strategies and processes to:

- Dynamically assess the quality of inventory across the network

- Predict which products and quantities your customers will require and disseminate that information across your organization

- We refresh the data on a daily, weekly or monthly basis – as frequently as needed – to best determine the right approach to drive positive financial impact

What you can do NOW!

Here are some steps you can take now to actively manage your inventory….and your cash flow:

- Continuously assess the quality of your inventory across Raw Materials, Work In Progress, Finished Goods

- Identify, plan, & execute the depletion of non-productive inventory from your warehouses, creating cash for your business

- Identify excess and/or shortage of inventory with dynamic Days of Supply analysis (optimize what to make/buy to meet ever-changing demand)

- Optimize inventory planning with dynamic safety stock and lead time assessment (only make/buy what you need to meet target turns)